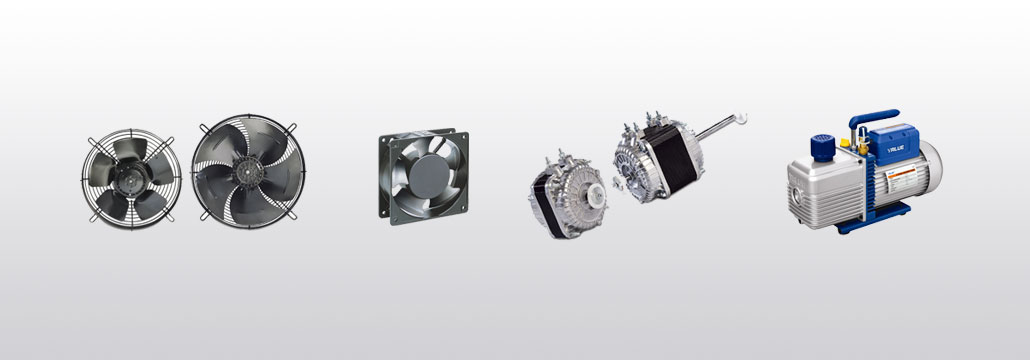

Axial Fans

Shaded Pole Motors

Vacuum Pump

The purpose of a vacuum pump is to remove moisture and air from an A/C-R system. Modern systems are built tighter and charges are more critical. That means these systems have a greater sensitivity to moisture and other contaminants, making thorough evacuation more important than ever before.

A single stage vacuum pump just dumps out to the exhaust, while a two or dual stage pump the exhaust of the first stage goes to inlet of the second stage, which is then exhausted by bubbling through the oil resovior — that’s why you hear two stage pumps gurgle quite a bit when first vacuuming down, then they “quiet” down.

Micron levels will be much lower with two or dual stage vacuum pumps. The lower the micron level the better.

A Guide to Selecting the Right Size Vacuum Pump:

The more air a vacuum pump moves, the faster it can reach an acceptable vacuum. A smaller vacuum pump takes more time to evacuate a system than one that’s the correct size for the job.

| System: | ||

| Up to 10 tons (35kW); Domestic Refrigeration, Passenger Cars | 1.2 CFM | 1.5 CFM |

| Up to 30 tons (105kW); Residential A/C, Panel Trucks & RV’s | 4 CFM | 3 CFM |

| Up to 50 tons (176kW); Rooftop A/C systems, Tractor/Trailers, Buses | 6 CFM | 5 CFM |

| Up to 70 tons (246kW) | 10 CFM | – |

Condensate/Drain Pumps

A condensate pump is a specific type of pump used to pump the condensate (drain water) produced in an HVAC (heating or cooling), refrigeration, condensing boiler furnace or steam system. A condensate pump is used when a gravity (or downhill sloping) condensate drain line to either the outdoors or a floor drain is not feasible.

Aspen has become the global leader for mini condensate pumps. Mini pumps operate on a float switch mechanism which detects the presence of water in the drain pan, activating the pump. Aspen offerSave the most complete and high performance range of mini pumps in the world.

- Small & powerful

- Quiet & reliable

- Market leading

- Plug & play