History of Copper

Archaeological evidence indicates that copper was used as far back as 10,000 years ago in western Asia. During the prehistoric Chalcolithic Period, societies discovered how to extract and use copper to produce ornaments and implements. As early as the 3rd-4th Millennium BC, copper was actively extracted from Spain’s Huelva region. Around 2500 BC, the discovery of useful properties of copper-tin alloys led to the Bronze Age.

It has been documented that Israel’s Timna Valley provided copper for the Pharaohs. Papyrus records from ancient Egypt reveal that copper was used to treat infections and sterilize water. The island of Cyprus is known to have supplied much of the copper needed for the empires of ancient Phoenicia, Greece, and Rome. Since copper was principally mined on Cyprus, hence the origin of the name of the metal as Cyprium, “metal of Cyprus”, later shortened to Cuprum.

The discoveries and inventions in the late 18th and early 19th Centuries by Ampere, Faraday, and Ohm propelled copper into a new era. Demonstrating excellent electrical conducting and heat transfer characteristics, copper played a pivotal role in launching the Industrial Revolution.

Copper Mining

Until the mid 1960s, copper and copper alloy tube was produced exclusively by extrusion or piercing to produce tube shells for subsequent drawing. Extrusion involves heating a billet above the re-crystallization temperature and then forcing the metal through an orifice in a die and over a mandrel held in position within the die orifice. The clearance between mandrel and die determines the wall thickness of the extruded tube shell. Extrusion pressure varies with alloy composition, lubricant, and die design with the copper-nickel alloys requiring very high pressures.

In rotary piercing, one end of a heated cylindrical billet is fed between rotating work rolls that lie in a horizontal plane and are inclined at an angle to the axes of the billet and are driven forward toward the piercing plug that is held in position between the work rolls.

Extruded or pierced tube shells are then cold drawn to smaller sizes mainly on bull blocks for copper and draw benches for the copper alloys. With either type of machine, the metal is cold worked by pulling the tube though a die that reduces the diameter. Concurrently, wall thickness is reduced by drawing over a plug or mandrel that may be either fixed or floating. Tubes may be annealed at any intermediate stage when drawing to smaller sizes is required because of the metal’s work hardening. In the mid 1960s, welded copper tube produced from strip without the use of a filler metal became commercial. This was soon followed by forge and fusion welded heat exchanger tube in sizes up to 3 1/8 in. (7.94 cm).

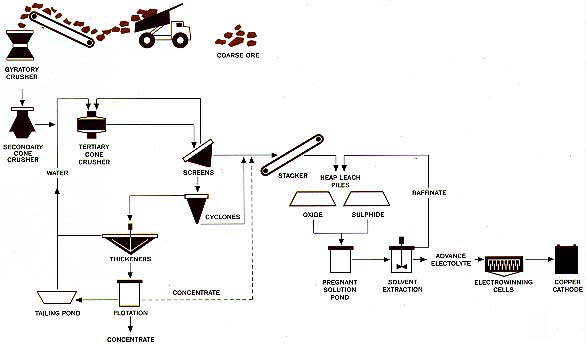

Copper Mining – Basic copper mine process, from mine to metal.

The flow-sheet shows a basic copper mine process, from mine to metal. There are two distinct types of copper ore, the sulfide ore and the oxide ore. The sulfide ores are beneficiated in flotation cells, while the oxide ores are generally leached. First the copper ore from a open pit mine is blasted, loaded and transported to the primary crushers. Then the ore is crushed and screened, with the fine sulfide ore (~-0.5 mm) going to froth flotation cells for recovery of copper. The coarser ore goes to the heap leach, where the copper is subjected to a dilute sulfuric acid solution to dissolve the copper. Then the leach solution containing the dissolved copper is subjected to a process called solvent extraction (SX). The SX process concentrates and purifies the copper leach solution so the copper can be recovered at a high electrical current efficiency by the electro-winning cells. It does this by adding a chemical reagent to the SX tanks which selectively binds with and extracts the copper, is easily separated from the copper (stripped), recovering as much of the reagent as possible for re-use. The concentrated copper solution is dissolved in sulfuric acid and sent to the electrolytic cells for recovery as copper plat(cathodes). Copper cathodes are purchased by uniflow as our raw material and then manufactured into copper tubing.

Copper, a stable, natural, and recyclable material, has been used continuously in piping for over 2000 years. Archeologists have recovered a portion of a water plumbing system from the Pyramid of Cheops in Egypt. After 5,000 years, the copper tubing was still in serviceable condition.

The demand for copper will continue to be met by the discovery of new deposits, technological improvements, efficient design, and by taking advantage of the renewable nature of copper through reuse and recycling. As well, competition between materials, and supply and demand principles, contribute to ensuring that materials are used efficiently and effectively.

Copper is an important contributor to the national economies of mature, newly developed and developing countries. Mining, processing, recycling and the transformation of metal into a multitude of products creates jobs and generates wealth. These activities contribute to building and maintaining a country’s infrastructure, and create trade and investment opportunities. Copper will continue to contribute to society’s development well into the future.